Specialized Equipment

Ceres, operates, and maintains one of the largest inventories of disaster recovery equipment in the United States.

Ceres currently has access to more than 1,000 pieces of equipment through contract with its wholly-owned subsidiary Ceres Environmental, Inc. Equipment includes tub and horizontal grinders, shredders, excavators of various sizes, loaders, bulldozers, custom-built knuckleboom self-loading trucks and numerous other pieces of support equipment.

Connected Around the World

Ceres enjoys long-established working relationships with subcontract firms throughout the United States and its territories. These relationships provide us with the ability to rapidly expand and contract our equipment and personnel needs based on the specific requirements of each given project. We have rapid access to thousands of pieces of additional equipment, including debris handling and reduction equipment, hauling vehicles, bucket trucks, cranes, and other specialized and heavy equipment.

Mobile Command Centers

Ceres Mobile Command Centers are also designed and outfitted specifically for disaster recovery response missions and are complete self-supporting units. These mobile stations are designed with generators and backup fueling systems to provide heat, cooling, and power. Each unit is equipped with communication systems, computer systems, video systems with uplink capabilities, emergency safety supplies, water, emergency food rations, and other support equipment necessary for the initial phase of a response mission.

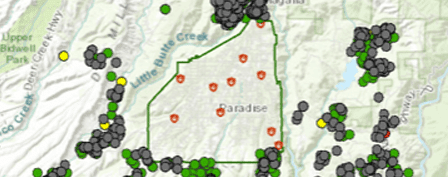

GIS Software

Ceres has customized the latest Environmental Systems Research Institute Geographic Info System software suite, ArcGIS, ArcGIS Collector, Survey123, and ArcGIS Navigator to facilitate project geographical control and provide readable digital maps to all levels of operational and quality control management.

Our ArcGIS based system provides Ceres, its subcontractors, suppliers, and customers the following benefits:

- Digital real-time sector, zone, and subzone maps for assignments and dispatch

- More timely and accurate estimates of debris quantities, types, and densities enabling the deployment of the most efficient collection crew configurations

- Continual tracking of debris collection operation progress, including debris types and quantities, to facilitate monitoring and zone/subzone closeout

- Visual and geospatial documentation of specific concerns at the field level to facilitate deficiency tracking and minimize rework

- A common operating picture within Ceres and amongst all of our partners, through the ability to share data collected from the tool’s various sources

Automated Debris Management System

The Automated Debris Management System is currently being integrated to replace the “old” method of paper tickets for tracking debris generated on disaster recovery missions. The automated system uses computerized field technologies to electronically track load generation information.

Some of our specialized equipment includes:

- Self-Loading Debris Trucks

- GPS Equipped Heavy Equipment (Dozers/Motorgraders)

- Mobile, Hurricane Proof Command Centers

- Satellite Communications

- Debris Monitoring Stations

- Side Dump Trucks

- Live Bottom/Walking Floor Trailers

- Beach Cleaners

- Specialized Watercraft for Debris Removal

- Demolition Equipment:

- CAT 385 Ultra High Reach Demolition Excavator

- Labounty MSD100R 21000 Pound Demo Shear

- CAT MP20 Processor

- Genesis GPD900R Shear

-

- RexWorks Megagrinder

- Horizontal and Tub Grinders (CBI, Diamond Z)

- Rubble Master Concrete Crusher

- Sandvik Concrete Crusher

- Powerscreen Warrior 1800 Screening System

- Doppstadt DW 3060 Shredder

- Air curtain burners